I'm sure all mountain webcam watchers will have been glued to the feeds this week: some flakes falling softly, some arriving as blasts from Siberia: the base layers have been falling all over Europe and it makes me think about the logistics of life in the Alps ... when do you decide that building must stop? That the cranes must be dismantled, the lifts must be made fit to run, the log piles are safely delivered to the restaurants to provide a thousand and one Calzones and the summer vehicles and the cattle are safely down from the pastures ...

With such a fluid start to the ski season, how on earth do they plan?

And so it begins ...

Login

To Create or Answer a Topic

Started by Penelope Pitstop in Ski Chatter 22-Nov-2013 - 8 Replies

Penelope Pitstop posted Nov-2013

Dave Mac

reply to 'And so it begins ...' posted Nov-2013

What a good question.

The cranes do not generally get dismantled. If they are in position, then they generally stay there, and restart in mid March.

Small and medium sized resorts tend to have fixed season opening and closing dates. There are a lot of logistics involved, particularly if a resort is heavily dependent on tour operators. They set their dates a year ahead.

Larger ski areas may open some of their lifts, as they will get business from locals and people withing driving distance. They need to be able to set up lift personnel, first aiders, ski hire and restaurants.

Slightly linked to this is the ground temperature for switching on snow making, although with advanced additives, this is getting less critical.

Log piles are usually all in stock by September/October.

Cattle are usually brought down from the Alms in late September, early October, and there is often an associated mountain festival. Also, the alm workers leave the summer farms.

At the end of my first ski season, I was offered a job to look after a summer farm in Austria!

All the summer cattle fencing has to be dismantled, and snow machines set in place.

I'm pretty sure there must be some logistical preparation in hospitals and medical centres, and the nature and number of accidents will change.

New skis to be delivered to ski hire shops, temporary staff to be taken on in all the village and ski related businesses.

The cranes do not generally get dismantled. If they are in position, then they generally stay there, and restart in mid March.

Small and medium sized resorts tend to have fixed season opening and closing dates. There are a lot of logistics involved, particularly if a resort is heavily dependent on tour operators. They set their dates a year ahead.

Larger ski areas may open some of their lifts, as they will get business from locals and people withing driving distance. They need to be able to set up lift personnel, first aiders, ski hire and restaurants.

Slightly linked to this is the ground temperature for switching on snow making, although with advanced additives, this is getting less critical.

Log piles are usually all in stock by September/October.

Cattle are usually brought down from the Alms in late September, early October, and there is often an associated mountain festival. Also, the alm workers leave the summer farms.

At the end of my first ski season, I was offered a job to look after a summer farm in Austria!

All the summer cattle fencing has to be dismantled, and snow machines set in place.

I'm pretty sure there must be some logistical preparation in hospitals and medical centres, and the nature and number of accidents will change.

New skis to be delivered to ski hire shops, temporary staff to be taken on in all the village and ski related businesses.

Edited 1 time. Last update at 22-Nov-2013

Ian Wickham

reply to 'And so it begins ...' posted Nov-2013

Some webcams are on all year always worth a look ... :shock:

Penelope Pitstop

reply to 'And so it begins ...' posted Nov-2013

Thanks Dave - interesting stuff - I would have been very tempted by the offer to look after a farm in Summer! That's partly what made me think about it, Ian - have kept an eye on the ones at Val Thorens, Courmayeur, La Rosiere etc as I always find it interesting to watch ski areas I'm familiar with in winter through the year, but it was the frantic finishing off of the lift at VT on the 360 degree camera that prompted the post!

SwingBeep

reply to 'And so it begins ...' posted Nov-2013

The procedure is more or less the same here.

The first animals come down from the high alpine pastures at the end of August.

Building work usually stops before the middle of December as concrete doesn't cure properly without additives if the air temperature falls below 5 degrees. Many of the construction workers then go and work in the ski resorts, one of my friend's works as bricklayer in the summer and a ski instructor in the winter. Some of the idle plant is use for snow clearance.

The lift companies carry out lift maintenance over the summer. If temperatures are low enough snow making starts in November, although the use of additives is not prohibited here (I'm pretty sure there're banned in Austria) in practice they are only used in exceptional circumstances due to cost. Artificial snow is very expensive; it costs about 4 Euros per cubic metre.

If there is enough snow the large resorts will open what they can operate with their full time staff. Zermatt managed to increase the open runs to 100km this weekend, they could have opened some more runs in the Gornergrat sector, but they haven't got enough staff. The smaller resorts will often try and open a few runs at weekends from the beginning of December, but the season doesn't start properly until about the middle of December. The end of the season is determined by when Easter falls if it's early we get a shorter season if it's late a longer one

The A&E departments at the local hospitals are larger than the local population requires, out of season there are no queues. During the season they can get quite busy, especially on Sundays if the weather's nice and it hasn't snowed for a bit. To cope with the extra work load they employ extra staff for the season, usually from Germany.

Firewood is supplied by the forest service, they are the only people allowed to cut down trees in the forests. Full logs cost from 40 Francs a cubic metre, sawn and split to fire ready size 80 Francs transport is extra. All we have to do is download a form fill it out, email it back and they deliver it a few days later.

The first animals come down from the high alpine pastures at the end of August.

Building work usually stops before the middle of December as concrete doesn't cure properly without additives if the air temperature falls below 5 degrees. Many of the construction workers then go and work in the ski resorts, one of my friend's works as bricklayer in the summer and a ski instructor in the winter. Some of the idle plant is use for snow clearance.

The lift companies carry out lift maintenance over the summer. If temperatures are low enough snow making starts in November, although the use of additives is not prohibited here (I'm pretty sure there're banned in Austria) in practice they are only used in exceptional circumstances due to cost. Artificial snow is very expensive; it costs about 4 Euros per cubic metre.

If there is enough snow the large resorts will open what they can operate with their full time staff. Zermatt managed to increase the open runs to 100km this weekend, they could have opened some more runs in the Gornergrat sector, but they haven't got enough staff. The smaller resorts will often try and open a few runs at weekends from the beginning of December, but the season doesn't start properly until about the middle of December. The end of the season is determined by when Easter falls if it's early we get a shorter season if it's late a longer one

The A&E departments at the local hospitals are larger than the local population requires, out of season there are no queues. During the season they can get quite busy, especially on Sundays if the weather's nice and it hasn't snowed for a bit. To cope with the extra work load they employ extra staff for the season, usually from Germany.

Firewood is supplied by the forest service, they are the only people allowed to cut down trees in the forests. Full logs cost from 40 Francs a cubic metre, sawn and split to fire ready size 80 Francs transport is extra. All we have to do is download a form fill it out, email it back and they deliver it a few days later.

Dave Mac

reply to 'And so it begins ...' posted Nov-2013

It is interesting to compare.

Austrian snow making regulation is province-based. I think that Snowmax is generally permitted, this being a bacteria fundamental. There seems to be greater importance attached to water resource and usage. In Tyrol, high reservoirs must be created. These are generally set up, so as to create a summer recreational option.

With much of Austria still operating small scale farming operations, individual farmers will cut timbers for themselves, and arrange to supply neighbours. Local knowledge is crucial, as "fire ready size" matters. Kachelofens are individually built, and each will have their own optimum log length.

Some years ago, there was a large scale re-organisation of hospitals in our area of Tirol, accompanied by a revision of helicopter service provision. Alongside this, GP surgeries are often equipped with X-ray equipment, so incidents up to bone breaks are dealt with locally. The over/under capacity provision issue remains the same, though.

Returning to snow making, €4/m3 seems very costly. I wonder if that changes when using water pumped from the valley c/w reservoir storage?

Austrian snow making regulation is province-based. I think that Snowmax is generally permitted, this being a bacteria fundamental. There seems to be greater importance attached to water resource and usage. In Tyrol, high reservoirs must be created. These are generally set up, so as to create a summer recreational option.

With much of Austria still operating small scale farming operations, individual farmers will cut timbers for themselves, and arrange to supply neighbours. Local knowledge is crucial, as "fire ready size" matters. Kachelofens are individually built, and each will have their own optimum log length.

Some years ago, there was a large scale re-organisation of hospitals in our area of Tirol, accompanied by a revision of helicopter service provision. Alongside this, GP surgeries are often equipped with X-ray equipment, so incidents up to bone breaks are dealt with locally. The over/under capacity provision issue remains the same, though.

Returning to snow making, €4/m3 seems very costly. I wonder if that changes when using water pumped from the valley c/w reservoir storage?

Edited 1 time. Last update at 23-Nov-2013

SwingBeep

reply to 'And so it begins ...' posted Nov-2013

It is isn't it; I think the differences in the way things are done are largely due to the differing terrain and climate.

Regarding the use of snowmaking additives, I double checked before posting. In Austria, unless the law has changed very recently they are defiantly prohibited. There are even regulations regarding the quality of water that can be used for snowmaking. In most of the states bathing water quality is acceptable, but in Tirol it must be drinking water quality and there are limits on mineral content.

The price I gave is the average price; it ranges from 3 - 5 Euros depending on the type of machine, propeller machines are more expensive to operate than lances and the temperature and humidity. I think wherever possible they try to avoid pumping the water uphill as it's very costly. The Swiss have recently developed a lance that doesn't require any electricity it just needs a 200 metre height difference between the lance and the reservoir http://www.slf.ch/ueber/organisation/schnee_permafrost/projekte/Nessy2/index_EN if adopted should bring costs down considerably.

In Tirol alone they make 40 million cubic metres of artificial snow each winter, with which they cover 4500 hectares of piste. To produce it requires 16 million cubic metres of water and 90 gigawatt hours of electricity. In total it costs between 120 and 160 million Euros, staggering oder.

The traditional heating stove here is the 'Giltsteinofen' they are made out of soapstone and usually have the family crest carved on the front. All the ones I have seen were roughly the same size which presumably accounts for the standard size of firewood.

Regarding the use of snowmaking additives, I double checked before posting. In Austria, unless the law has changed very recently they are defiantly prohibited. There are even regulations regarding the quality of water that can be used for snowmaking. In most of the states bathing water quality is acceptable, but in Tirol it must be drinking water quality and there are limits on mineral content.

The price I gave is the average price; it ranges from 3 - 5 Euros depending on the type of machine, propeller machines are more expensive to operate than lances and the temperature and humidity. I think wherever possible they try to avoid pumping the water uphill as it's very costly. The Swiss have recently developed a lance that doesn't require any electricity it just needs a 200 metre height difference between the lance and the reservoir http://www.slf.ch/ueber/organisation/schnee_permafrost/projekte/Nessy2/index_EN if adopted should bring costs down considerably.

In Tirol alone they make 40 million cubic metres of artificial snow each winter, with which they cover 4500 hectares of piste. To produce it requires 16 million cubic metres of water and 90 gigawatt hours of electricity. In total it costs between 120 and 160 million Euros, staggering oder.

The traditional heating stove here is the 'Giltsteinofen' they are made out of soapstone and usually have the family crest carved on the front. All the ones I have seen were roughly the same size which presumably accounts for the standard size of firewood.

Dave Mac

reply to 'And so it begins ...' posted Nov-2013

Giltsteinofen! That is a beautiful structure. Not obvious where it is loaded, maybe the top.

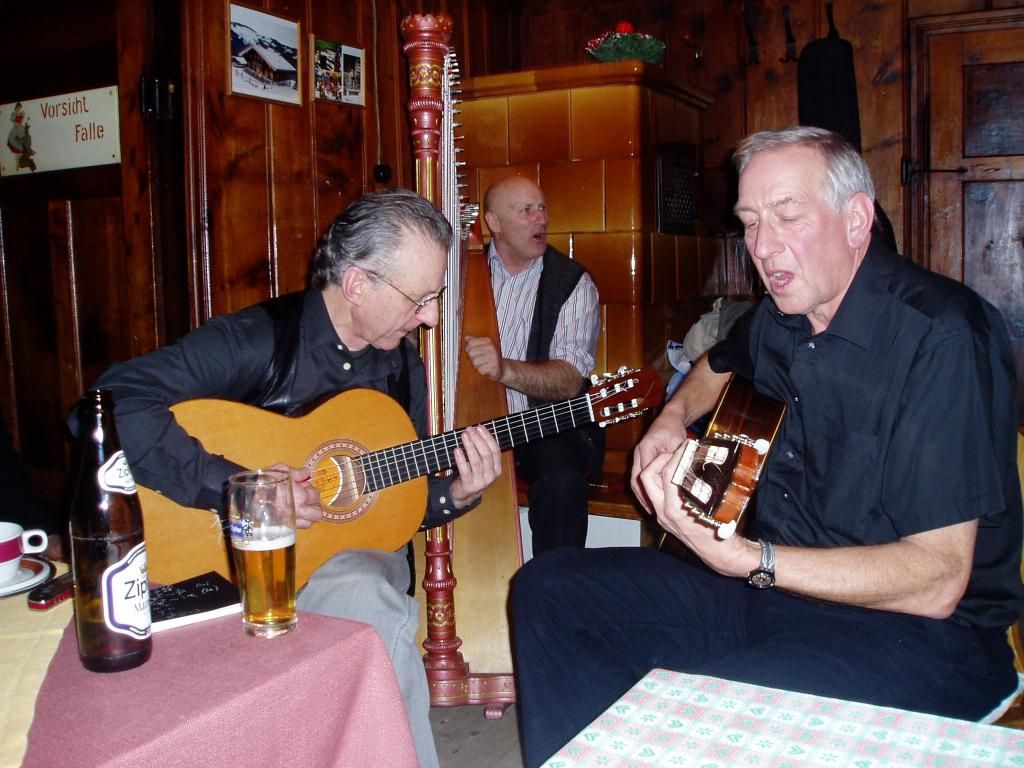

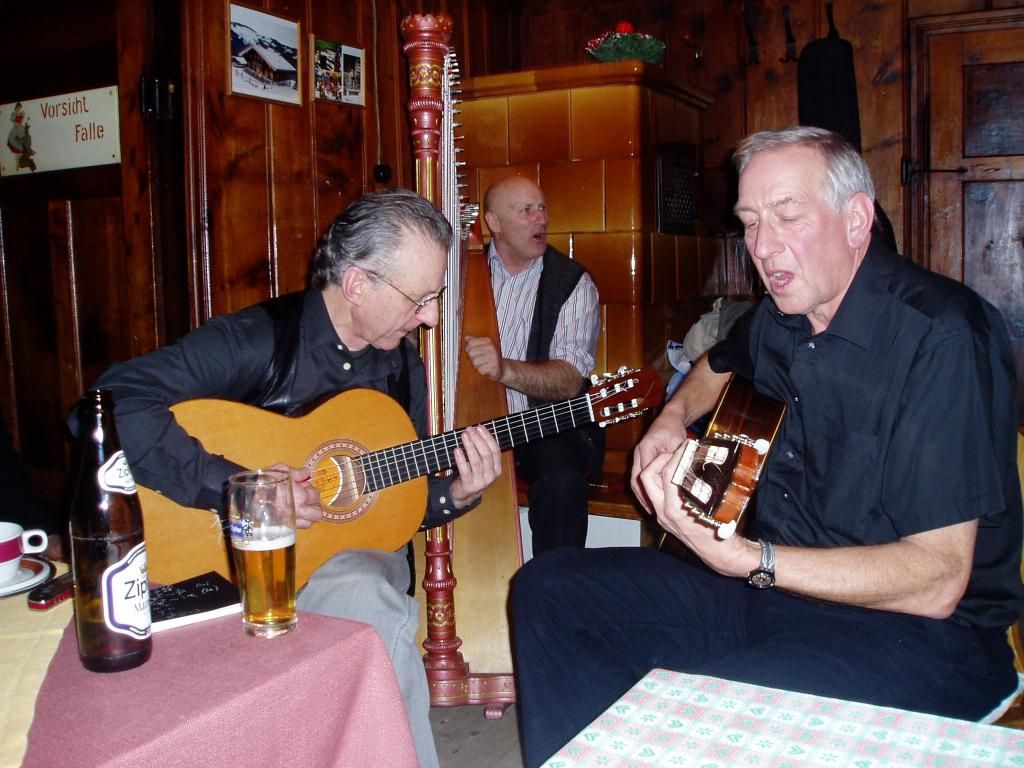

This is the Kachelofen in the Bichlwirt, a Welsh guy called Andrew, Herbert Thaler, and meself. The Bichlwirt is over 550 years old, and the front room is original.

So the log length is really important, they only loaded it once a day.

This is the Kachelofen in the Bichlwirt, a Welsh guy called Andrew, Herbert Thaler, and meself. The Bichlwirt is over 550 years old, and the front room is original.

So the log length is really important, they only loaded it once a day.

Topic last updated on 24-November-2013 at 23:41